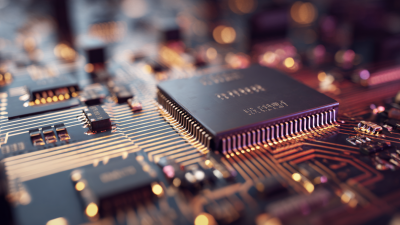

In the rapidly evolving field of electronics, the significance of circuit board manufacturing cannot be overstated. As the backbone of modern electronic devices, circuit boards play a crucial role in ensuring the functionality and reliability of products ranging from smartphones to medical devices. With increasing demands for higher quality and efficiency, manufacturers face the challenge of optimizing their processes without compromising on performance. This article presents the top ten practical tips designed to enhance both the quality and efficiency of circuit board manufacturing, providing valuable insights that can help manufacturers streamline operations and achieve higher production standards.

By implementing these strategies, circuit board manufacturers can not only improve yield and reduce waste but also foster a culture of continuous improvement within their organizations. As competition intensifies and customer expectations rise, organizations must stay ahead by adopting innovative techniques and best practices. The following sections will delve into each tip, offering clear and actionable guidance that can assist manufacturers in navigating the complexities of circuit board production in today’s dynamic market.

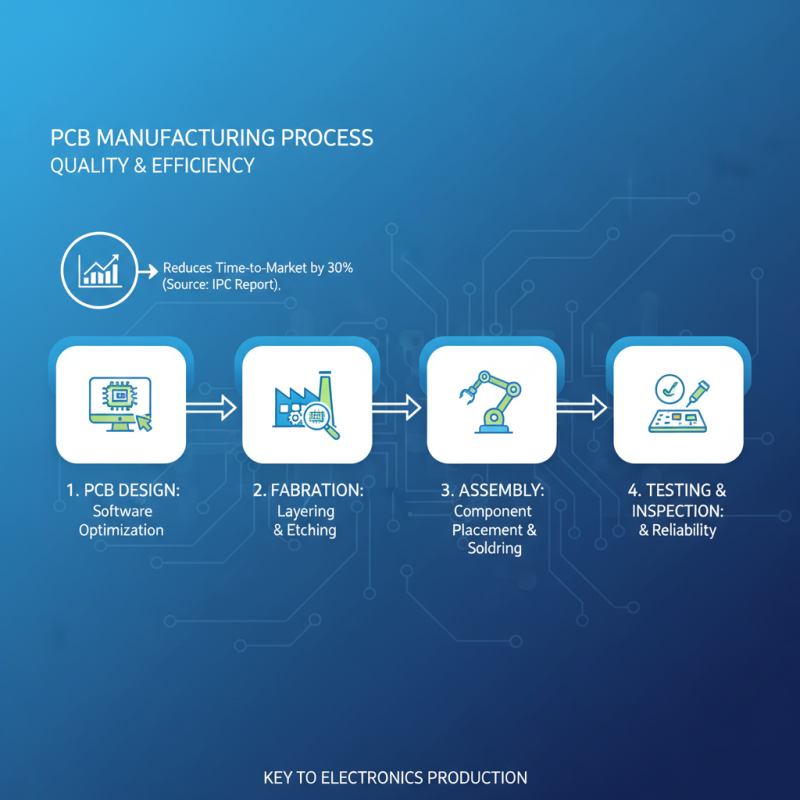

The process of circuit board manufacturing plays a crucial role in the overall electronics production landscape. Understanding the foundational techniques involved in this process can significantly enhance both quality and efficiency. Initially, the manufacturing process begins with PCB design, leveraging software tools to optimize layout and minimalize signal interference. According to a recent industry report from IPC, an organization dedicated to the electronics manufacturing sector, implementing advanced design software can reduce the time-to-market by nearly 30%, highlighting the importance of efficient design practices.

Once the design is complete, the fabrication phase commences, which includes several key steps such as material selection, lithography, etching, and solder mask application. The choice of materials, particularly substrates like FR-4, influences the thermal performance and reliability of the final product. Furthermore, data from the Electronics Industry Association suggests that accurate etching processes can minimize defects by up to 50%, reinforcing the need for precision in creating circuit board pathways. Transitioning to automated processes in manufacturing is another step that not only boosts production speed but also enhances quality control, resulting in fewer errors and a more consistent end product.

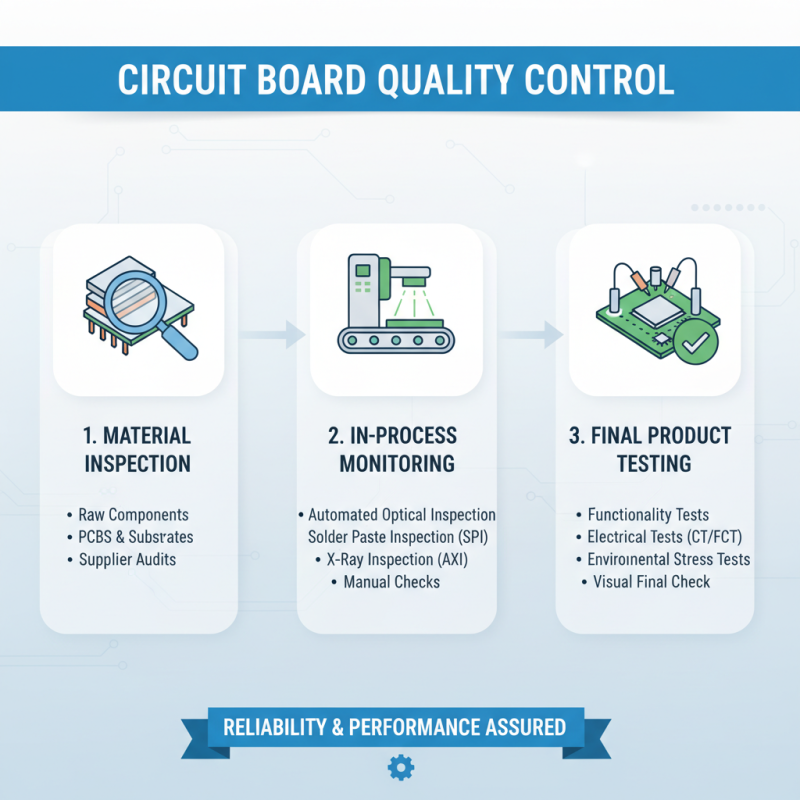

Quality control measures are essential in circuit board production to ensure the final product meets the necessary standards and performs reliably in its intended application. One of the primary strategies is the implementation of thorough inspection processes at various stages of manufacturing. This includes initial material inspections, in-process monitoring, and final product testing. By employing automated optical inspection systems, manufacturers can detect defects such as misalignments or missing components early in the production cycle, reducing the chances of costly rework or product failures.

Another critical aspect of quality control is the adherence to stringent process documentation and standard operating procedures (SOPs). These guidelines not only standardize manufacturing processes but also provide a framework for training employees on best practices. Keeping detailed records of production batches allows for traceability, enabling manufacturers to analyze data for continuous improvement. Furthermore, regular audits of production processes help identify areas for enhancement and ensure compliance with industry standards, ultimately leading to higher quality circuit boards and increased customer satisfaction.

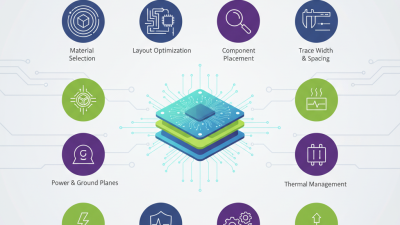

The quality of circuit boards largely depends on the materials chosen for their manufacture. Selecting the right base substrate is essential, as materials such as FR-4, a glass-reinforced epoxy laminate, offer excellent mechanical and thermal properties. This substrate not only provides structural support, but also ensures optimal electrical performance. Additionally, the use of high-frequency materials like PTFE (Teflon) is critical for applications requiring minimal signal loss, enhancing both speed and reliability.

In addition to substrates, the choice of conductive materials plays a pivotal role in circuit board manufacturing. Copper is the standard for conductive pathways due to its excellent conductivity and availability, but advancements in metal deposition techniques are leading to the adoption of alternatives like silver in specialized applications. Furthermore, incorporating high-quality solder masks and surface finishes can significantly impact the durability and overall performance of the circuit board. These essential materials collectively contribute to enhancing the quality and efficiency of circuit boards, ensuring they meet the demanding standards of modern electronic devices.

In the fast-paced world of PCB production, enhancing efficiency is crucial for meeting the increasing demands of technology. Implementing innovative techniques not only boosts productivity but also ensures high-quality outputs. One effective approach is the automation of design processes using advanced software tools. These systems allow for faster alterations and extensive simulations, reducing the likelihood of errors and shortening lead times.

Another key strategy is the adoption of lean manufacturing principles. This involves analyzing workflows to identify and eliminate waste, ensuring that resources are allocated effectively. By streamlining production processes, manufacturers can significantly reduce costs while maintaining a high standard of quality. Furthermore, incorporating real-time monitoring systems can provide insights into production performance, allowing for immediate adjustments where necessary.

Maintaining a well-trained workforce is equally vital. Investing in continuous training ensures that employees are well-versed in the latest techniques and technologies. Encouraging a culture of quality at every stage of production empowers teams to take ownership and responsibility, directly contributing to enhanced efficiency and product excellence. By focusing on these innovative techniques, PCB manufacturers can not only improve their operations but also position themselves as leaders in a competitive industry.

| Tip No. | Tip Description | Expected Benefit | Implementation Difficulty |

|---|---|---|---|

| 1 | Use Advanced CAD Tools | Improved design accuracy | Medium |

| 2 | Implement Automated Testing | Reduced defects | High |

| 3 | Choose Quality Materials | Enhanced durability | Low |

| 4 | Optimize PCB Layout | Improved performance | Medium |

| 5 | Maintain Clean Manufacturing Environment | Reduced contamination | Medium |

| 6 | Train Staff Regularly | Increased productivity | Medium |

| 7 | Use Multi-layer Boards | Compact design | High |

| 8 | Incorporate Design for Manufacturability (DFM) | Streamlined production process | High |

| 9 | Regular Quality Control Checks | Consistent quality | Medium |

| 10 | Feedback Loop with Customers | Enhanced customer satisfaction | Low |

The collaboration within PCB manufacturing teams is crucial for enhancing both quality and efficiency in circuit board production. Each team member, from design engineers to production staff, plays a vital role in the overall manufacturing process. When these individuals work collaboratively, they can identify potential issues early in the design phase, leading to more robust solutions and a reduced need for rework. Effective communication ensures that all team members are aligned with project goals and deadlines, fostering an environment where creativity and innovation can thrive.

Moreover, collaboration can significantly streamline processes, minimizing delays and ensuring the timely delivery of products. When teams employ collaborative tools and practices, they can efficiently share information and updates, which helps in maintaining consistent quality standards throughout the manufacturing stages. This interconnected approach not only improves workflow but also enhances team morale, as every member feels valued and invested in the project’s success. As a result, fostering a culture of collaboration within PCB manufacturing teams is not just beneficial but essential for achieving optimal outcomes in production quality and operational efficiency.