Starting your own PCB board manufacturing business is an exciting venture. The demand for printed circuit boards (PCBs) is growing rapidly. This growth presents a unique opportunity for entrepreneurs.

However, diving into PCB board manufacturing isn't without challenges. You will face technical complexities and financial hurdles. Understanding the manufacturing process is critical. You'll need to invest in quality materials and equipment. Establishing a reliable supply chain can be daunting, but it is essential for success.

Reflecting on your strategy is crucial. Mistakes may happen, and learning from them is part of the journey. Networking with others in the electronics industry can provide valuable insights. Stay updated with industry trends and customer needs to stay competitive. Your passion and dedication will drive your PCB board manufacturing venture forward.

Researching the PCB market is crucial. Start by identifying current trends and demands. You can explore various sectors, such as automotive, consumer electronics, or telecommunications. Each sector has unique requirements. Understanding these needs helps define your niche.

The next step is to analyze competitors. Look at their offerings, pricing, and target audiences. You might discover gaps in their services. Perhaps certain materials or quick turnaround times are missing. This can be a chance for you to stand out. However, avoid overly ambitious plans that stretch resources too thin. Focus on specific segments where you can excel.

Engaging potential customers is vital. Conduct surveys or interviews to gather insights. Ask what features they value most in PCB manufacturing. This feedback can shape your business strategy. Be prepared for criticism; it’s constructive. Accepting imperfections in your initial approach can lead to improvements over time.

| Aspect | Details |

|---|---|

| Market Size | Estimated at $60 billion in 2023 and expected to grow at a CAGR of 6.5% |

| Key Industries | Consumer Electronics, Automotive, Medical Devices, Aerospace |

| Common PCB Types | Rigid, Flexible, Rigid-Flex, Multi-layer |

| Target Customers | Startups, OEMs, and SMEs in electronics manufacturing |

| Important Regulations | RoHS compliance, IPC standards, UL certification |

| Startup Costs | Estimated initial investment of $50,000 to $500,000 |

| Competitor Analysis | Analyze local and global competitors focusing on technology and pricing |

| Marketing Strategies | Online advertising, trade shows, partnerships with design firms |

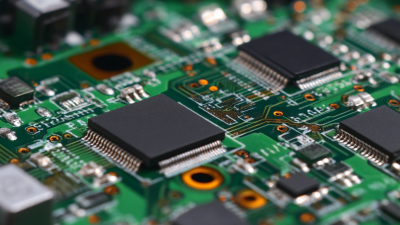

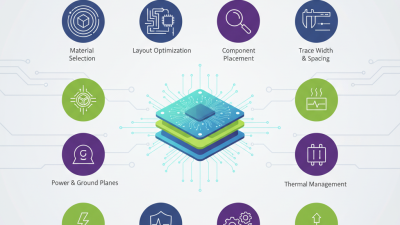

PCB manufacturing involves several critical steps. First, you need to design the circuit board using specialized software. This design phase includes laying out the tracks and pads. It can be detailed and intricate, requiring precision. Mistakes in this stage can lead to production delays. Revisions may take longer than expected.

Once the design is ready, the actual manufacturing begins. Materials like copper-clad laminate are used. The production process includes etching, drilling, and plating. Each step has a specific technology associated with it. For example, etching removes excess copper. Issues may arise during plating, such as uneven layers. Regular monitoring is critical to avoid errors.

Quality control is another essential part of PCB manufacturing. Inspecting each board ensures they meet functional standards. Testing can sometimes reveal flaws. It’s frustrating but necessary. You may need to adjust your processes based on these outcomes. Adaptability is key in this industry, and reflection on what can improve is invaluable.

Securing funding for a PCB board manufacturing business can be challenging. Start by assessing your initial investment needs. Equipment is often expensive. Consider the costs of materials, labor, and overhead. Prepare a detailed budget that outlines these costs. This will help you understand how much funding you require.

Next, creating a solid business plan is crucial. This document should include your market analysis. Identify your target customers and competitors. Understand their needs and how your business can fulfill them. Outline your marketing strategy and sales plan. Financial projections are also important. They demonstrate your potential profitability to investors. Emphasize your unique selling points.

Reflect on potential challenges. Many businesses underestimate operational costs. Some overlook the importance of networking. Creating partnerships can lead to opportunities for funding. Always be open to feedback on your plan. It may reveal gaps in your strategy you had not considered. Keeping a flexible approach can help you adjust your business model as needed.

Starting a PCB board manufacturing business requires careful planning. Setting up a facility is one of the first steps. Choose a location that offers enough space for production and storage. A clean environment is crucial for preventing contamination. Make sure you have proper ventilation and control humidity levels.

Acquiring the right equipment is next. You will need a variety of machines including a photoplotter, laser cutter, and laminator. Each piece of equipment has its own requirements. Research different options to find what fits your budget. Consider used equipment, but inspect it thoroughly. There could be hidden issues you need to address.

Think about your workflow. A well-organized layout can save time and reduce mistakes. You might find it challenging to manage logistics in the beginning. Developing efficient processes takes practice and adjustment. Mistakes will happen; learn from them to improve your operations. It’s important to remain adaptable and open to new ideas.

This bar chart represents the estimated investment amounts for various essential equipment required to set up a PCB board manufacturing business. The values reflect typical costs associated with different types of equipment necessary for the manufacturing process.

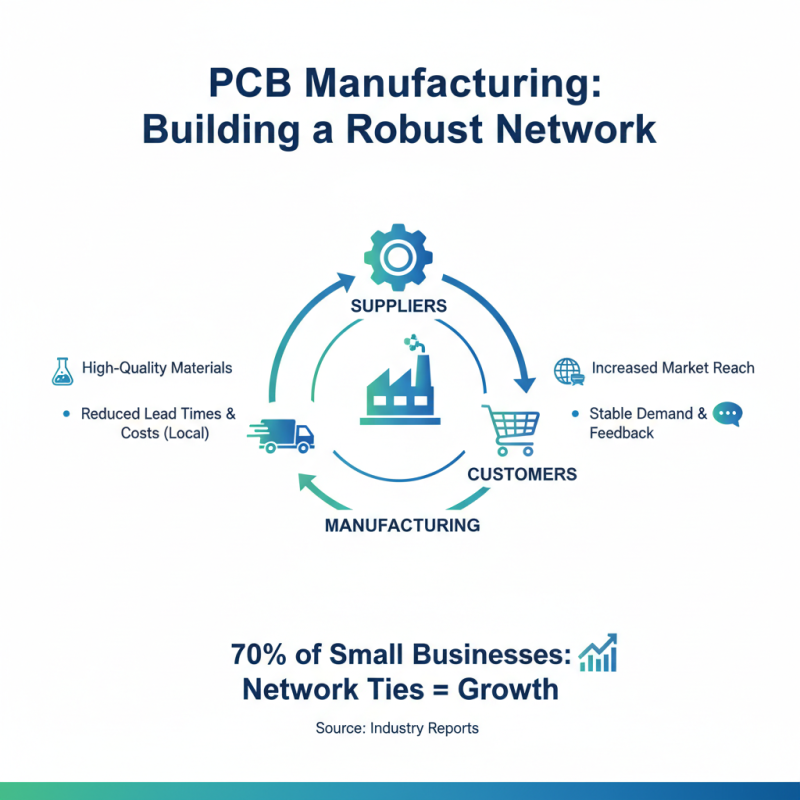

Building a robust network of suppliers and customers is crucial for any PCB board manufacturing business. According to industry reports, about 70% of small businesses cite network ties as a key factor in their growth. Establishing reliable relationships with suppliers ensures access to high-quality materials at competitive prices. A local supplier can reduce lead times and shipping costs, helping your business stay agile.

Connecting with potential customers is equally important. Industry analysis indicates that about 55% of PCB manufacturers gain most of their clients through referrals. Attend trade shows and industry conferences to meet potential customers face-to-face. Leverage social media platforms to showcase your capabilities. Showcase your work online, even when it's not perfect. Transparency builds trust. Discuss setbacks openly; it adds credibility to your expertise.

Communication is paramount. Regular follow-ups with suppliers and clients keep relationships strong. Surveys show that 60% of customers value ongoing communication. They appreciate being updated on projects and timelines, even when challenges arise. Utilize feedback effectively, as it can guide necessary adjustments. Balancing supplier relationships while nurturing customer connections can be challenging, but managing both is essential for sustainable growth.