Selecting the right circuit board for your project can be daunting. As noted by Dr. James Smith, a leading expert in electronics design, "Choosing a circuit board requires careful consideration." His insight highlights the importance of understanding your specific needs.

When embarking on a project, the type of circuit board greatly influences performance. Factors like size, complexity, and materials matter. A well-suited circuit board can enhance functionality and reliability. However, many overlook these aspects, leading to unexpected issues later.

Consider the functionality you need. Are you designing for durability or flexibility? Many professionals struggle with these choices. They might rush into decisions, resulting in mistakes. A circuit board should align with your project's goals, making careful selection essential.

Choosing the right circuit board starts with understanding your project's specific needs. Different applications require various circuit board types. For instance, high-frequency applications need materials like Rogers or PTFE. These materials offer better performance than standard FR-4. The IPC Global Market Information Database indicates that materials alone can influence costs by up to 30%.

Power requirements also play a crucial role. Higher wattage demands necessitate boards designed to handle extra heat. Failure to consider heat dissipation can result in board failure. A recent study showed that 47% of circuit board failures were due to thermal issues. It’s important to choose a PCB design that includes thermal management solutions. More complexity can increase manufacturing costs, so weigh your options carefully.

Size limitations should not be overlooked either. Compact designs can save space, but might lead to fewer design options. Many engineers struggle with this trade-off. A board that is too small may lack necessary features. Understanding these limits upfront is key. Gathering insights from field reports will help clarify your needs. Keep refining your requirements as you progress.

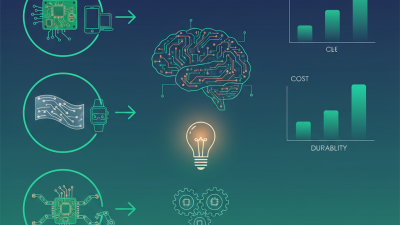

When selecting a circuit board, understanding the various types is crucial. There are several key types: printed circuit boards (PCBs), flexible circuit boards, and rigid-flex boards. Each type has unique applications. According to industry reports, the PCB market is expected to reach $100 billion by 2025, driven by demand in consumer electronics.

PCBs are widely used in devices like smartphones and computers. Flexible circuit boards are ideal for wearable tech due to their ability to bend and conform. Rigid-flex boards combine both features, making them suitable for more complex applications. Choosing the right type depends on your project’s specific requirements.

Tips: Always consider the environment of use. Factors such as temperature and moisture can affect performance.

Another aspect to think about is the manufacturing process. It can impact cost and lead times significantly. Ensuring you have clear specifications is vital. Common mistakes often arise from vague requirements, leading to project delays.

Tip: Double-check your specifications with potential manufacturers. Miscommunication can be costly. Make adjustments early in the process to avoid issues later.

| Circuit Board Type | Description | Typical Applications | Layer Count |

|---|---|---|---|

| Single-Sided PCB | Circuit design on one side of the substrate. | Simple electronics, toys, and appliances. | 1 layer |

| Double-Sided PCB | Circuit components on both sides with vias for interconnection. | Audio devices, power supplies, and communication devices. | 2 layers |

| Multilayer PCB | Three or more layers of conductive material embedded within a substrate. | Computers, smartphones, and sophisticated electronic equipment. | 3 or more layers |

| Flexible PCB | Flexible substrate allowing bending and folding. | Wearable devices, medical equipment, and automotive applications. | Varies |

| Rigid-Flex PCB | Combination of rigid and flexible circuit boards. | Smartphones, tablets, and compact medical devices. | Varies |

Selecting the right materials for circuit board construction is crucial. Various materials offer different properties, influencing performance and durability. For example, FR-4 is widely used for its balance of cost and performance, but it may not suit every project. Consider the specific needs of your project before choosing.

Thermal conductivity is key for heat management. Materials like aluminum can dissipate heat effectively. However, they can be heavier and more expensive. Think carefully about the application. If weight is a concern, you might prefer lighter materials like polyimide.

Mechanical stability is another important factor. Some materials can warp under pressure. This is an issue during assembly and operation. Testing your circuit board under real conditions can reveal unexpected problems. Reflect on your choices and be open to adjustments. Your project’s success often depends on these material evaluations.

Selecting the right circuit board for your project is crucial. Cost factors play a vital role in this decision. According to a recent industry report, the average cost of a single-layer PCB can range from $2 to $5 per square inch. In contrast, multi-layer boards can cost upwards of $10 per square inch. Price fluctuations are common, influenced by materials and manufacturing processes.

When analyzing costs, consider the quantity of boards required. Higher volume orders can significantly reduce the per-unit cost. Manufacturers often offer discounts for bulk orders. However, this could lead to overproduction, resulting in unused inventory. Balancing production scale with demand is key.

**Tip:** Always request quotes from multiple suppliers. This comparison can save money. Also, factor in shipping and lead time. Paying a little extra for faster delivery can be worthwhile in urgent situations.

Another critical factor is the complexity of your design. Simple circuits are more cost-effective. Complex designs may require advanced materials, increasing costs. It’s essential to assess your project needs carefully. Avoid unnecessary upgrades that don't benefit the functionality.

**Tip:** Create a detailed list of requirements. Prioritize must-haves and nice-to-haves. This approach helps clarify spending and keeps tracks of expenses. Maximize your budget by avoiding rushed decisions.

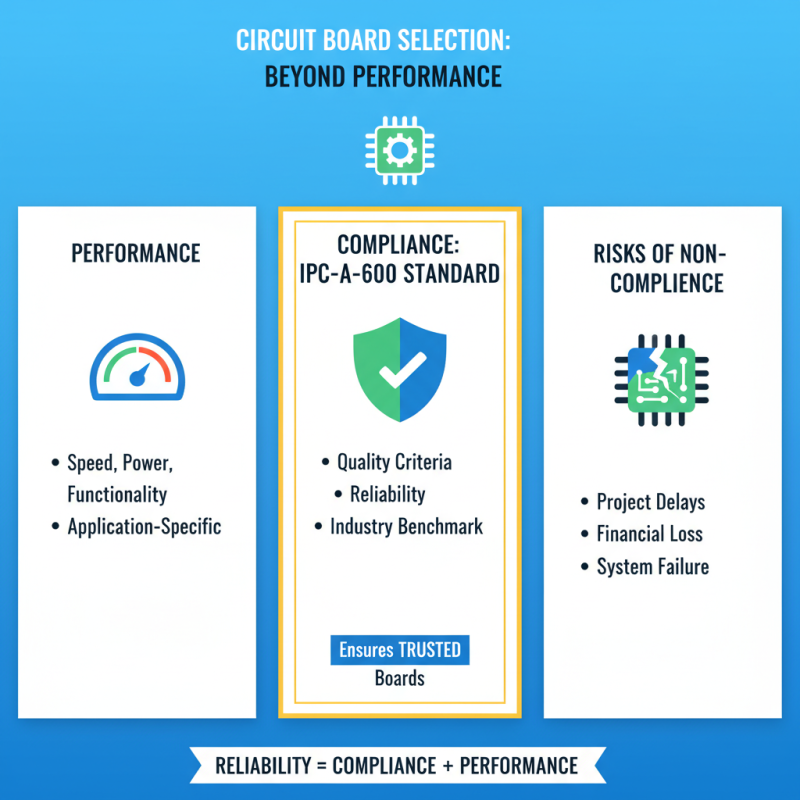

Selecting the right circuit board goes beyond performance. Compliance with industry standards is critical. According to the IPC a-600 standard, boards must meet strict quality criteria to ensure reliability. Non-compliance can lead to failures, impacting finances and timelines.

When choosing a circuit board, ensure it meets relevant regulations like RoHS or REACH. These standards reflect environmental safety and chemical regulations. A report from the International Electrotechnical Commission indicates that over 30% of PCB defects arise from non-compliance with these regulations.

Tips: Always check certification documents before finalizing a board. Engage in discussions with manufacturers about their compliance processes. Analyze your project needs against these regulations early in the design phase to avoid costly revisions later. Ensuring compliance upfront can save time and money down the road. Missing these details may result in delays or redesigns that can jeopardize project success.