In the realm of electronics manufacturing, the significance of PCB fabrication cannot be overstated. Printed Circuit Boards (PCBs) serve as the backbone of modern electronic devices, providing the essential infrastructure that connects various components and allows them to communicate effectively. As technology advances and the demand for smaller, more efficient devices grows, PCB fabrication has emerged as a critical factor in ensuring product reliability, performance, and cost-effectiveness.

The process of PCB fabrication encompasses a range of techniques, from designing and layering to etching and soldering. Each stage is crucial in determining the final quality of the electronic product. High-quality fabrication processes not only enhance the electrical performance of devices but also reduce the risk of defects that could lead to product failures. Moreover, advancements in PCB fabrication technologies have introduced new materials and methodologies, enabling manufacturers to push the boundaries of what is possible in electronics design.

Ultimately, understanding the vital role of PCB fabrication is essential for anyone involved in electronics manufacturing. It impacts everything from the scalability of production to the overall lifecycle of electronic devices. As the industry continues to evolve, a deep knowledge of PCB fabrication will undoubtedly serve as a cornerstone for successful manufacturing practices.

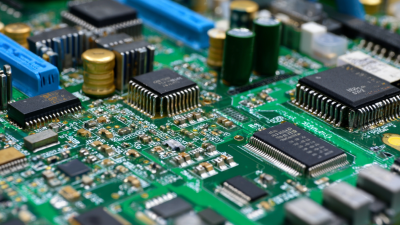

PCB fabrication is a fundamental process in electronics manufacturing, serving as the backbone for virtually all electronic devices. This intricate process involves designing and producing printed circuit boards (PCBs), which are essential for the mechanical support and electrical connections of electronic components. The precision and quality of PCB fabrication directly influence the overall performance, reliability, and longevity of the final product. As electronic designs evolve and become more complex, the demand for high-quality PCB fabrication becomes even more critical, ensuring that all aspects of a device function harmoniously.

Moreover, the role of PCB fabrication extends beyond mere assembly and connection. It encompasses a variety of techniques, such as etching, solder mask application, and surface finish selection, which are crucial for enhancing electrical performance, reducing signal interference, and optimizing thermal management. By employing advanced fabrication technologies, manufacturers can achieve tighter tolerances and improved miniaturization, thereby enabling the development of smaller and more efficient electronic devices. As a result, effective PCB fabrication is not only about creating a physical substrate but also about supporting innovation and advancing the capabilities of electronics in various applications.

| Aspect | Description | Impact on Manufacturing |

|---|---|---|

| Design Accuracy | Precision in PCB design ensures proper functionality and compatibility of components. | Reduces errors, minimizes rework, and increases overall quality. |

| Material Selection | Choosing appropriate substrate materials impacts performance and durability. | Influences thermal management, signal integrity, and product lifespan. |

| Manufacturing Techniques | Advanced fabrication techniques enhance precision and efficiency. | Enables faster production times and reduces costs. |

| Testing and Quality Assurance | Rigorous testing ensures reliability and safety of PCBs. | Minimizes the risk of failure in end products, thus boosting consumer trust. |

| Regulatory Compliance | Adhering to industry standards and regulations ensures safe products. | Avoids legal issues and enhances marketability. |

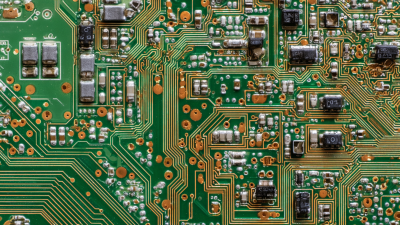

The PCB fabrication process is a critical component of electronics manufacturing, encompassing a series of meticulously planned steps. The journey begins with the design phase, where engineers create detailed schematics and layouts using CAD software. This blueprint guides all subsequent steps, ensuring that every component is accurately placed on the printed circuit board.

After finalizing the design, the next step involves the production of photomasks, which are essential for transferring the circuit pattern onto the PCB substrate. Following this, the substrate undergoes lamination and etching, where layers of copper are added and unwanted copper is removed to form the desired circuitry. This phase is crucial, as precision during etching directly affects the board's functionality and performance.

Tips: Always double-check the design files for any errors before sending them to fabrication. Small mistakes in the layout can lead to significant issues during assembly. Additionally, maintain clear communication with your fabrication partner to ensure any technical specifications are clearly understood and adhered to during production. By following these key steps diligently, manufacturers can achieve high-quality PCBs that meet the rigorous demands of the electronics industry.

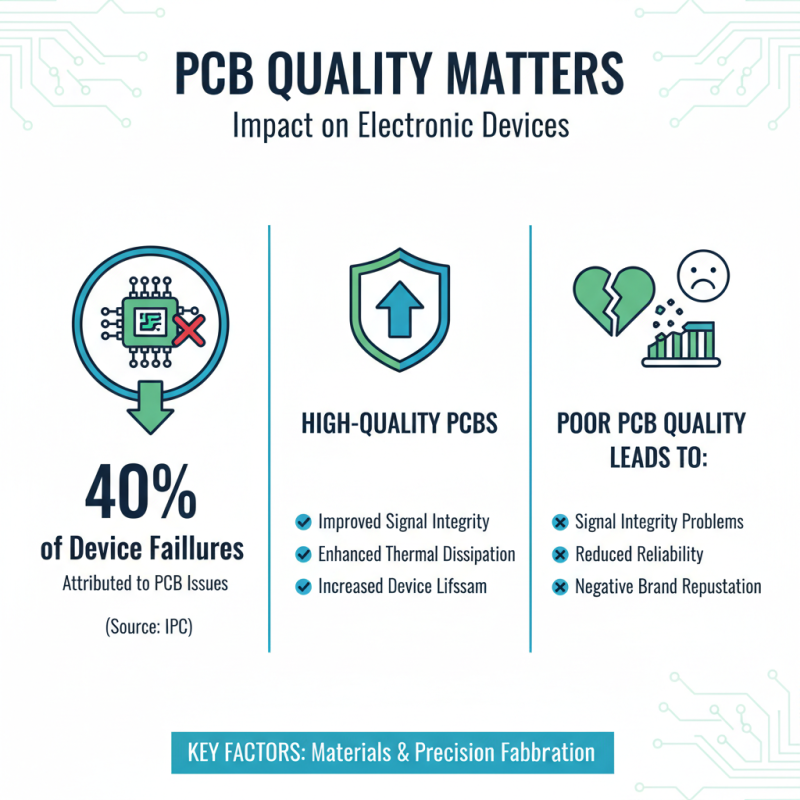

The quality of printed circuit boards (PCBs) plays a pivotal role in determining the overall performance and reliability of electronic devices. According to a report by the IPC Association Connecting Electronics Industries, nearly 40% of electronic device failures can be attributed to PCB-related issues. This statistic underscores the importance of utilizing high-quality materials and precision fabrication techniques during PCB manufacturing. Poor PCB quality can lead to signal integrity problems, thermal dissipation issues, and reduced lifespan of the devices, ultimately impacting consumer satisfaction and brand reputation.

When considering PCB quality, it’s essential to focus on parameters such as layer alignment, trace routing efficiency, and the integrity of solder joints. Data from the Electronics Industry Association suggests that optimal PCB designs can improve device performance by up to 30%, enhancing both efficiency and reliability. Moreover, investing in rigorous quality control processes during PCB fabrication, including automated optical inspection (AOI) and in-circuit testing (ICT), can significantly mitigate risks associated with faulty boards.

Tips: Always choose a PCB manufacturer with a solid track record and certification to ensure consistent quality. Regularly review and update your design specifications to align with emerging industry standards, which can help avoid potential pitfalls in performance and durability. Additionally, consider prototyping your designs to test and validate performance before mass production, ensuring that any issues can be identified and rectified early in the manufacturing process.

Printed Circuit Board (PCB) fabrication plays a pivotal role in the electronics manufacturing industry, yet it presents various challenges that can impact production efficiency and product quality. One prominent challenge is the complexity of circuit design, which often results in difficulties related to signal integrity and thermal management. According to a report by IPC, nearly 40% of engineers cite design issues as the root cause of PCB failures. This emphasizes the importance of thorough design verification and prototyping, allowing manufacturers to transition from concept to production with greater confidence.

Another significant hurdle in PCB fabrication is the handling of materials and processes. As the demand for miniaturization increases, so does the reliance on advanced materials and manufacturing techniques, such as multi-layer designs and high-density interconnections. This evolution requires stringent quality control measures, as even minor defects can lead to significant operational failures. A study from SMTA indicates that implementing automated inspection technology can reduce defects by more than 30%, ensuring reliable performance of PCBs in various applications.

Tips: Always invest in rigorous prototyping and testing phases to identify potential pitfalls early. Utilize automated tools to enhance quality control and minimize human error during the fabrication process. Lastly, keeping abreast of advancements in materials science can provide a competitive edge in PCB design and production, paving the way for innovative electronic solutions.

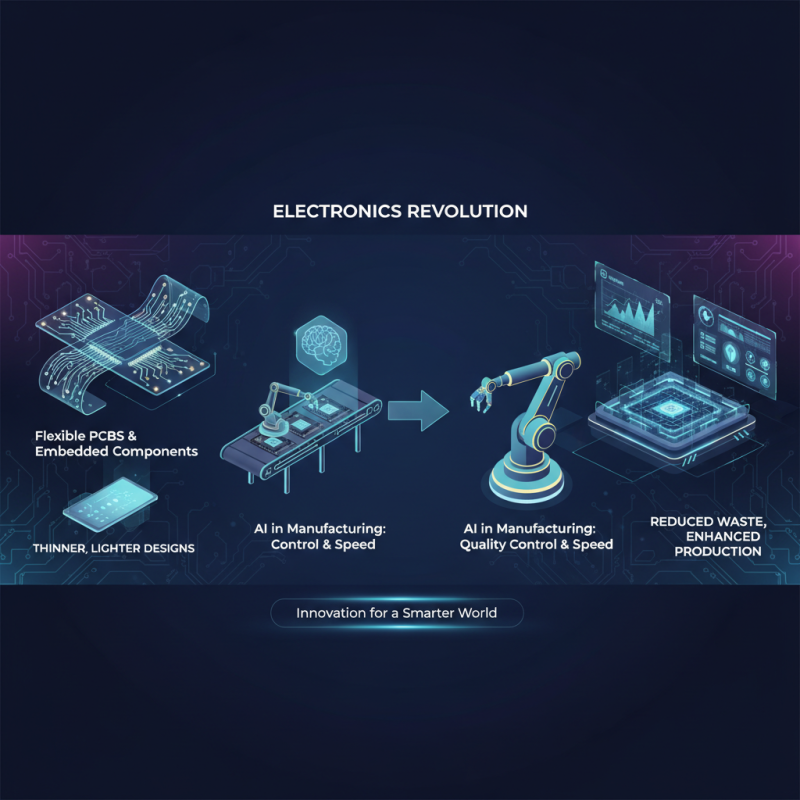

The future of PCB fabrication technology is poised to revolutionize the electronics manufacturing landscape. As the demand for smaller, more efficient devices increases, innovations such as advanced materials and automation in PCB fabrication will play a critical role. Technologies like flexible PCBs and embedded components allow for thinner and lighter designs, enabling more complex functions in compact spaces. Additionally, the integration of artificial intelligence in the manufacturing process can lead to better quality control, reducing errors and waste while enhancing production speed.

Tips: When considering new PCB technologies, manufacturers should invest in R&D to stay ahead of trends. Collaborating with suppliers who focus on sustainable materials can also contribute to more eco-friendly production processes, aligning with global sustainability goals.

Moreover, the rise of IoT devices demands more robust and reliable PCBs. Future trends indicate an increasing use of 3D printing, which offers rapid prototyping and customization that traditional methods cannot match. This not only shortens development cycles but also allows for innovative designs that can adapt to emerging consumer needs. Adopting modular designs can further streamline manufacturing and facilitate easier upgrades for consumers, ensuring long-term competitiveness in the market.

Tips: Embrace modular PCB designs to enhance scalability and adaptability. Investing in training for employees on emerging fabrication technologies can also empower your team to embrace innovations effectively.