In the rapidly evolving electronics industry, understanding different PCB board types is crucial. Dr. Helen Carter, a renowned expert in PCB design, once stated, “The right PCB board can transform your electronic project from concept to reality.” This insight underlines the significance of selecting the appropriate board type for specific applications.

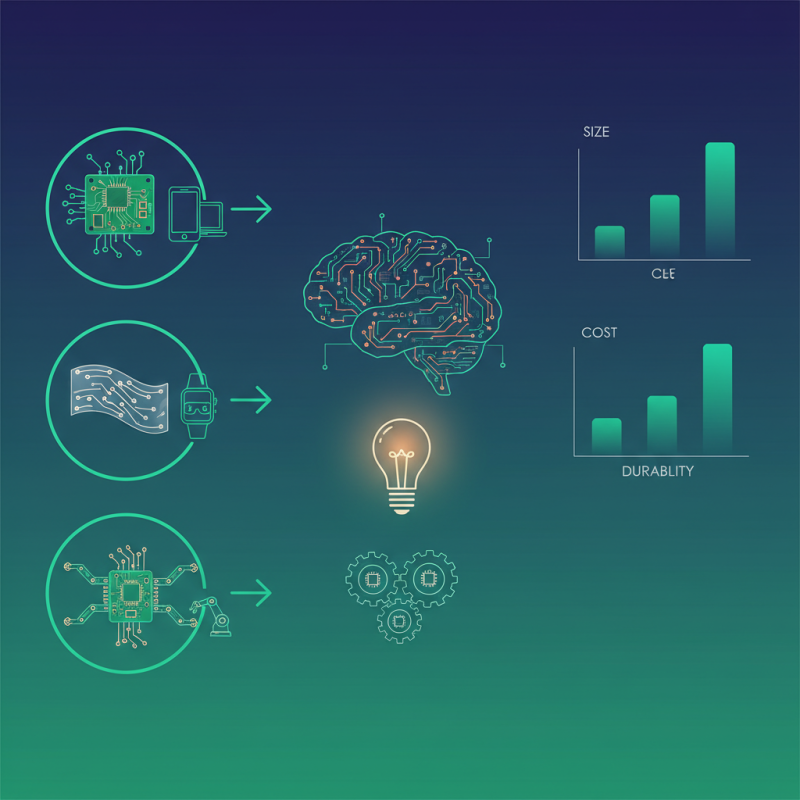

Various PCB board types exist, each serving unique functions. Rigid boards are common in consumer electronics, while flexible boards find use in wearable devices. The complexity of designs often leads engineers to choose hybrid solutions. Yet, not every engineer fully grasps this diversity. Misunderstanding can result in costly errors and project delays.

Navigating the options can be overwhelming. Each choice has pros and cons. Designers need to evaluate factors such as size, cost, and durability. Failure to consider these can lead to challenges in the manufacturing process. A thorough understanding of PCB board types is vital for successful electronics development. This knowledge ensures that projects meet both functional and aesthetic demands.

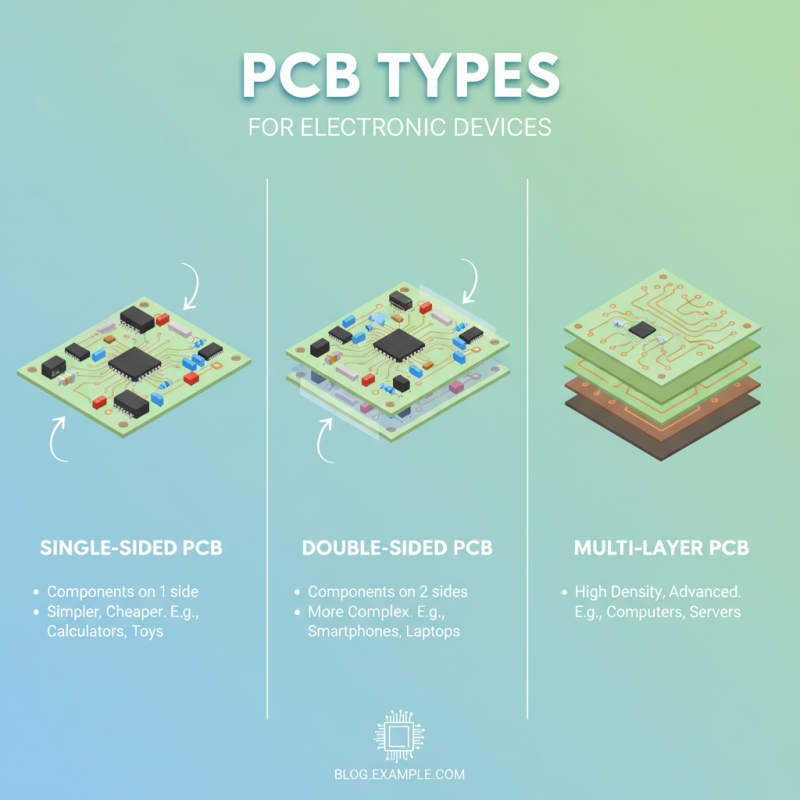

Printed circuit boards (PCBs) come in various types, each serving different functions in electronic devices. The most common types include single-sided, double-sided, and multi-layer boards. Single-sided PCBs have components on one side, making them simpler and cheaper. They are commonly found in less complex devices like calculators and toys. Conversely, double-sided boards allow for more components and greater complexity, suitable for devices like smartphones.

Multi-layer PCBs consist of three or more layers of circuitry. They are used in high-density applications, such as computers and industrial machines. However, designing these boards can be challenging due to complications in layering. The stacking of layers can lead to issues with heat dissipation and signal integrity. It is essential to consider these factors during design to avoid potential failures.

Flexible PCBs also deserve mention. They can bend and twist, making them ideal for compact designs like wearables. But flexibility can also lead to durability concerns. Sometimes connections may fail due to constant bending. Each PCB type has its strengths and weaknesses, prompting continuous reflection on the best choice for a specific application.

Printed Circuit Boards (PCBs) serve as the backbone of modern electronics. The fundamental components of PCB construction include substrates, conductive pathways, and solder masks. The substrate is usually made from materials like FR-4. This material has excellent electrical insulating properties and can withstand high temperatures. Conductive pathways, often copper traces, are etched onto the substrate. These pathways connect different electronic components, allowing them to communicate efficiently.

In 2021, a report highlighted that the global PCB market was valued at approximately $70 billion. As technology evolves, the demand for multi-layer and flexible PCBs increases. Flexible PCBs are crucial for portable devices, where space is limited. They can bend and twist, accommodating various designs. However, designing these boards can be challenging. Engineers face difficulties in ensuring reliability and durability without compromising flexibility. Mistakes can lead to faulty connections, which can be costly.

The solder mask, applied on top of the copper traces, prevents unintended connections. It also protects the board from environmental damage. Developing the right balance of thickness and material is essential. Yet, achieving perfection is complicated. Errors in PCB design can cause significant setbacks in production and performance. Memory and processing speeds can suffer if the PCB isn’t optimized. Understanding these components is essential for anyone involved in electronics today.

| PCB Type | Materials Used | Common Applications | Advantages |

|---|---|---|---|

| Single-Sided PCB | FR-4, phenolic | Consumer electronics, small devices | Cost-effective, easy to manufacture |

| Double-Sided PCB | FR-4, polyimide | Power supplies, automotive electronics | Higher density, better performance |

| Multi-Layer PCB | FR-4, high-frequency materials | Computers, telecommunication devices | Compact design, advanced circuitry |

| Rigid PCB | FR-4, copper | Medical devices, automotive applications | Durable, stable performance |

| Flexible PCB | Polyimide, polyester | Wearable devices, smartphones | Lightweight, adaptable to space |

| Rigid-Flex PCB | FR-4, polyimide | Aerospace, electronics | Combines rigidity and flexibility |

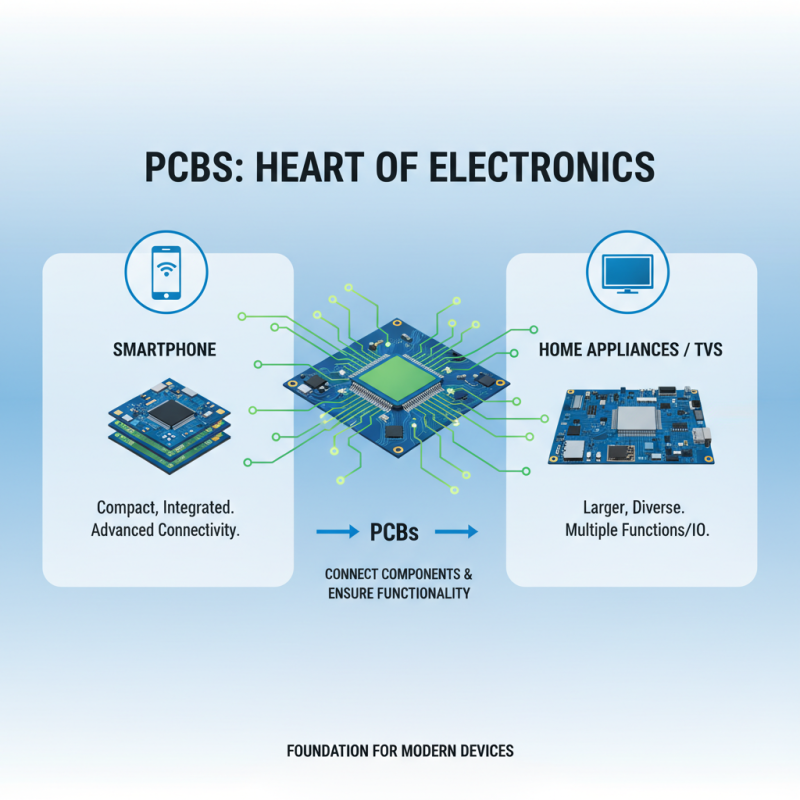

Printed Circuit Boards (PCBs) play a crucial role in consumer electronics. They provide the foundation for various devices. From smartphones to home appliances, PCBs connect components and ensure functionality. Their design often varies, depending on the application. In a smartphone, for example, the PCB is compact and integrated, allowing for advanced connectivity. A larger PCB might be used in televisions, supporting various inputs and outputs.

In gaming consoles, PCBs manage high-speed data transfer. This enables a seamless gaming experience. The layers of the PCB must be carefully designed for efficiency. Complex gaming systems require multiple layers to accommodate numerous connections. This complexity can lead to manufacturing challenges.

Tips: Always consider the PCB layout carefully. A good layout can enhance signal integrity. Choose the right materials for specific environments. This can improve durability and performance. Make sure to test prototypes thoroughly. Small errors in design can lead to significant failures down the line. Continuous reflection on design and function is essential for success.

Specialized PCBs play a crucial role in modern electronics. RF (Radio Frequency) PCBs are designed for high-frequency applications. They minimize signal loss and interference. These boards utilize specific materials to achieve consistent performance. Many industries rely on RF PCBs for communication devices and wireless technologies.

Flex PCBs are another interesting type. They are lightweight and can bend into various shapes. This flexibility makes them ideal for compact devices. Think of wearable tech, where space is limited. However, creating flexible designs requires careful consideration of material strength and durability. Overestimating capabilities can lead to failures.

Multi-layer PCBs combine several layers to accommodate complex circuits. These boards support intricate designs without increasing the footprint. They are widely used in computers and advanced electronics. Yet, there's a trade-off; manufacturing multi-layer boards can be more expensive and time-consuming.

Tips: Always assess the application needs before choosing a PCB type. Balancing performance and cost is key. Regularly revisiting design choices can improve outcomes.

This chart illustrates the growth percentages of various types of printed circuit boards (PCBs) in the electronics industry, focusing on RF, flexible, and multi-layer technologies. The data indicates a positive market trend for these specialized PCBs, with multi-layer PCBs experiencing the highest growth rate.

The landscape of PCB manufacturing is evolving rapidly. Recent innovations are reshaping how electronic devices are built. For instance, the use of flexible PCBs is on the rise. Reports indicate that the flexible PCB market is expected to grow by over 10% annually. This trend is driven by the demand for lightweight and compact designs in smartphones and wearable devices.

Moreover, advancements in materials are noteworthy. New composite materials offer better thermal performance. They enhance reliability in high-density circuits. Industry studies also highlight the rise of eco-friendly PCBs. As regulations tighten, manufacturers are urged to adopt sustainable practices. Yet, not all companies are adapting quickly enough. There's a gap between innovation and application, leading to potential waste in the industry.

Automation in manufacturing processes is another critical trend. Smart factories are streamlining production, improving efficiency by 30% in some sectors. However, not every company can afford these upgrades. Smaller manufacturers may struggle to keep pace with larger competitors. This disparity could lead to a market imbalance in the coming years. The future of PCB manufacturing is promising, but challenges remain.