The circuit board assembly industry is facing significant challenges as it moves towards 2026. According to a recent report by MarketsandMarkets, the global circuit board assembly market is projected to reach $24 billion by 2026, driven by the expanding electronics sector. However, improving efficiency remains crucial. Industry expert Dr. Emily Tran emphasizes, "Efficiency will be the key differentiator in circuit board assembly as we move forward."

Manufacturers are increasingly seeking ways to enhance their operations. Automation plays a vital role in this transformation. Yet, many companies struggle with the implementation of advanced technologies. While they invest in new machines, the lack of skilled labor can hinder progress. A recent survey by IPC revealed that 70% of manufacturers cite workforce shortages as a major obstacle.

Furthermore, quality control continues to be a pressing issue. Process inconsistencies can lead to increased waste and rework. This not only drives up costs but also impacts delivery timelines. Addressing these inefficiencies is essential for staying competitive. As the industry evolves, the need for adaptive strategies in circuit board assembly will only grow more critical.

In 2026, circuit board assembly efficiency is crucial for manufacturers. Streamlining processes can reduce costs and improve output. One effective strategy is optimizing workflow layouts. An efficient layout minimizes unnecessary movement. This can cut assembly time significantly. Evaluate current layouts regularly. Adjusting them can lead to better ergonomics and speed.

Automation is another key strategy. Automated machines can handle repetitive tasks faster than humans. However, not all tasks can be automated. Choosing the right processes for automation is essential. Sometimes, manual assembly is more flexible. Understand the balance. Also, staff training remains vital. Skilled workers enhance productivity. Ensure they are well-versed in the latest technologies.

Finally, consider implementing modular assembly techniques. This allows teams to work on separate components simultaneously. While it seems efficient, it also requires careful coordination. If mismanaged, it can lead to errors. Regular communication is important to avoid confusion. Reflection on these strategies can help improve overall assembly efficiency.

In 2026, circuit board assembly can significantly benefit from advanced automation technologies. These innovations streamline processes, reduce human error, and enhance overall productivity. Automated pick-and-place machines, for example, can precisely position components on the board, minimizing placement errors. However, reliance on this technology may also introduce challenges. What if the machines malfunction?

Implementing smart factory solutions can further increase efficiency. These systems use real-time data to optimize workflow and address bottlenecks. Yet, data privacy concerns must be addressed. Balancing efficiency with security is essential for sustainable progress. Workers may need retraining to adapt to these new systems. Transitioning to a fully automated workflow is not without its hurdles.

Advanced robotics alongside artificial intelligence could improve inspection accuracy. Automated inspection systems can quickly identify defects, reducing waste. But what happens when the system fails to detect a small flaw? Regular audits and human oversight remain crucial. The path to successful automation is filled with reflections on both opportunities and risks.

| Dimension | Current Value | 2026 Target Value | Change (%) |

|---|---|---|---|

| Production Speed (units/hour) | 150 | 250 | 66.67% |

| Assembly Accuracy (%) | 95 | 99.5 | 4.74% |

| Cost per Board ($) | 20 | 15 | -25% |

| Downtime (hours/week) | 10 | 2 | 80% |

| Labor Efficiency (%) | 75 | 90 | 20% |

Implementing lean manufacturing principles in circuit board production has the potential to significantly enhance efficiency. This approach eliminates waste in processes and optimizes resource allocation. For instance, streamlining assembly lines can reduce idle time and improve the flow of work. Workers may find themselves more engaged when empowered to identify areas of inefficiency. This empowerment sparks innovation and fosters a culture of continuous improvement.

While implementing lean practices, it's crucial to offer proper training and tools. Workers need to understand the why behind each change. Insufficient training can result in confusion or resistance. Occasionally, the principles may not yield immediate results. It's vital for teams to reflect on these challenges and adapt accordingly. Regular feedback loops can help in fine-tuning processes, ensuring that the assembly line remains agile and responsive to changing demands.

Moreover, organizing workstations is a key component of lean principles. Each tool should have a designated place, minimizing time spent searching. However, over-organizing can lead to rigidity, stifling creativity. Flexibility is necessary. A balance must be struck between structure and freedom. In conclusion, the pursuit of lean manufacturing in circuit board assembly is a powerful yet ongoing journey.

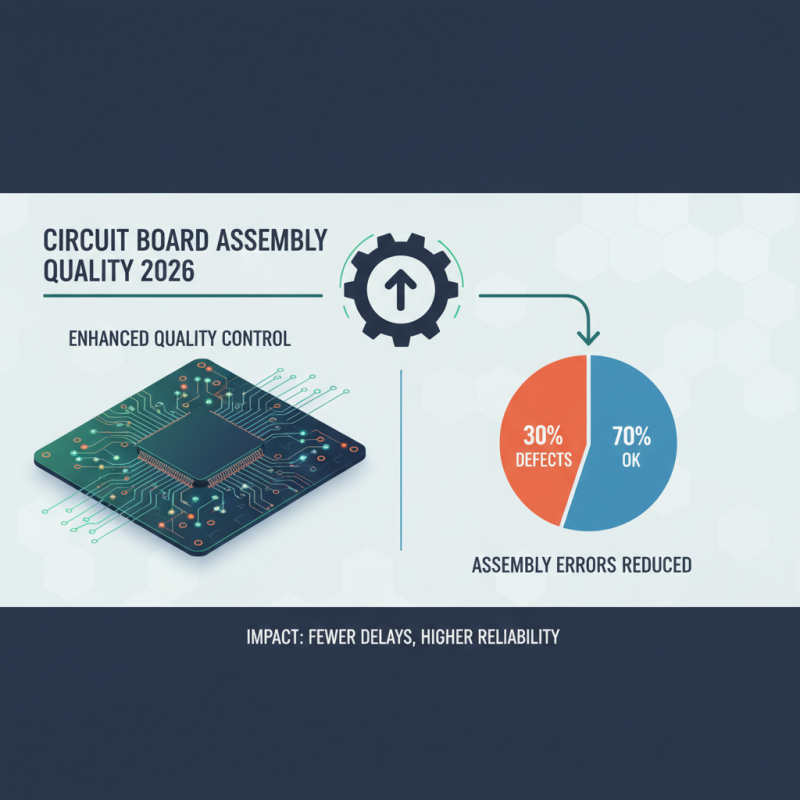

In 2026, enhancing quality control measures in circuit board assembly is crucial. The assembly process is complex, often leading to errors and delays. According to a recent industry report, about 30% of defects arise during assembly. Implementing robust quality control can reduce this figure significantly.

One effective measure is real-time monitoring. Continuous inspection can immediately identify flaws. A study showed that companies utilizing this method decreased defect rates by up to 25%. However, many facilities still rely on periodic checks, which can be inadequate. Regular audits reveal that less than 50% of assemblies consistently meet quality standards. This gap highlights the need for advancements.

Employee training is another critical area. Skilled workers are vital for maintaining high-quality standards. Yet, many companies struggle to invest in continual training. In fact, around 40% of assembly teams lack proper training. This results in inefficiencies and increased rework. It's essential to create a strong training program. With these improvements, circuit board assembly will become more efficient and reliable.

In 2026, improving circuit board assembly efficiency hinges on investing in employee training and skill development.

Training sessions must be hands-on.

Workers should engage in actual assembly tasks. They need to understand the equipment, tools, and techniques used daily.

Short workshops, perhaps lasting a few hours, could help reinforce knowledge.

Frequent practice is more effective than theoretical lectures.

Skill development goes beyond technical training.

It includes problem-solving and critical thinking exercises. Employees should learn to troubleshoot issues on the spot.

Real-world scenarios, like dealing with unexpected machinery failures, can boost their confidence.

Instilling a culture of continuous learning is essential. Employees should feel empowered to share ideas on improving processes.

Mistakes along the way provide valuable lessons. An open discussion about failures can enhance team cohesion and innovation.

It’s not just about knowing what to do; it’s understanding why it matters.