Designing an effective electronic circuit board (PCB) is a crucial aspect of modern electronic engineering that determines the performance and reliability of electronic devices. As technology continues to advance, the complexity of circuits increases, making the design process both challenging and essential. A well-designed electronic circuit board not only ensures the efficient functioning of electronic components but also contributes to the overall longevity and effectiveness of the device.

In this guide, we will explore ten essential tips that can significantly enhance your PCB design process. These tips aim to help engineers and designers understand crucial factors like layout, component placement, signal integrity, and thermal management, which are pivotal in creating a robust electronic circuit board. By implementing these best practices, you can avoid common pitfalls, streamline production, and improve the performance of your electronic devices. Whether you are a novice or an experienced designer, mastering these techniques will ultimately lead to more efficient and reliable electronic products.

Understanding the basics of electronic circuit board design is crucial for anyone looking to succeed in the field of electronics. At its core, a circuit board serves as a foundation for electronic components, providing the necessary pathways for electrical signals. This begins with a solid understanding of schematics and the functionality of each component, including resistors, capacitors, and integrated circuits. Grasping how these elements interact will enable designers to create efficient layouts that minimize potential issues like interference and signal loss.

Another fundamental aspect of circuit board design is the selection of appropriate materials and design techniques. The choice of substrate material can significantly affect performance, influencing factors like thermal management and electrical conductivity. Additionally, the layout process requires careful consideration of trace widths, spacing, and the arrangement of components to optimize performance and manufacturability. By focusing on these basics, designers can streamline the development process and create effective circuit boards that meet the desired specifications while ensuring reliability and durability.

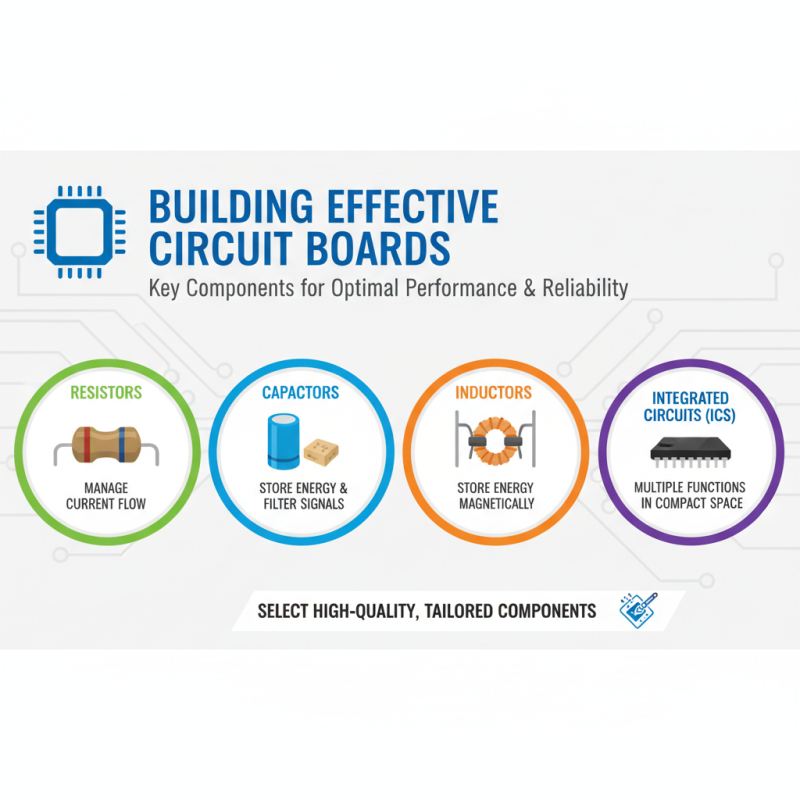

When constructing an effective electronic circuit board, selecting the right components and materials is pivotal to ensure optimal performance and reliability. The heart of any circuit board lies in its components, which typically include resistors, capacitors, inductors, and integrated circuits. Resistors manage the flow of current, while capacitors store energy and filter signals. Inductors, though less common, are used for their ability to store energy in a magnetic field. Integrated circuits serve multiple functions within a compact space, making them essential in modern circuit designs. Choosing high-quality components tailored to the specific requirements of the circuit can significantly enhance functionality and longevity.

In addition to the components, the choice of materials for the board itself plays a crucial role. The substrate, commonly made of materials like FR-4, provides a stable base for the components and ensures proper insulation. Copper is typically used for the conductive traces that connect different components, owing to its excellent conductivity and ease of fabrication. Furthermore, understanding thermal management is vital, as certain applications may generate heat that requires effective dissipation methods. Using heat sinks or selecting materials with better thermal conductivity can prevent overheating and ensure the circuit operates reliably under various conditions. Each material and component selection should align with the overall design goals, ensuring the circuit board performs as intended in its specific application.

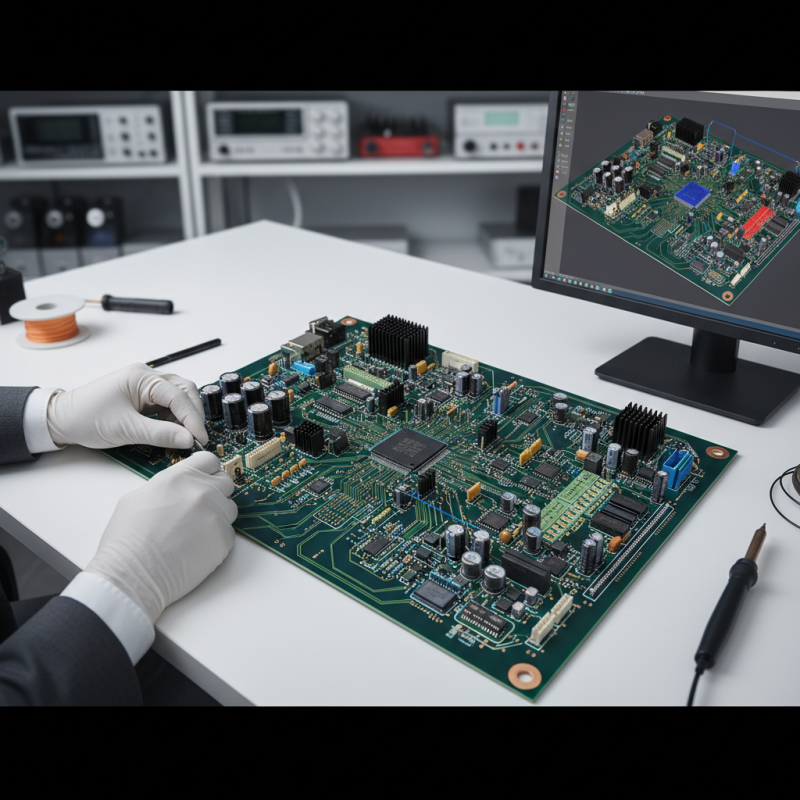

When embarking on circuit board development, choosing the right design software and tools is crucial for ensuring efficiency and accuracy. A robust circuit design program should provide a user-friendly interface while incorporating advanced features like real-time simulation and PCB layout capabilities. These features help designers visualize their circuits and identify potential issues before the fabrication stage. Furthermore, support for multiple layers and complex geometries is essential for modern electronic applications, allowing for more sophisticated designs.

In addition to core design software, auxiliary tools can significantly enhance the development process. Schematic capture tools enable designers to create and modify circuit blueprints intuitively, while simulation software helps in predicting how circuits will behave under various conditions. Additionally, tools for automated design rule checking can save time by ensuring that all specifications are met. By integrating these essential software and tools, designers can streamline their workflow, reduce errors, and ultimately create more reliable electronic circuit boards.

When it comes to designing an effective electronic circuit board, layout and routing play a crucial role in ensuring both functionality and reliability. According to industry studies, poor layout can lead to increased electromagnetic interference (EMI) and inefficient signal integrity, negatively affecting the overall performance of the device. To mitigate these issues, it’s essential to adopt best practices in PCB design.

One fundamental tip is to keep power and ground planes as solid and contiguous as possible. This helps minimize loop area and reduces the effects of EMI. Additionally, placing decoupling capacitors close to the power pins of integrated circuits can significantly stabilize power distribution, enhancing the circuit's reliability. Data from reports in the field suggest that following these guidelines can yield a reduction in noise levels by upwards of 30%.

Another critical factor in routing involves ensuring that the trace widths are appropriate for the current load. The IPC-2221 standards outline specific guidelines to determine the optimal trace width for various currents, helping designers avoid thermal issues that can arise from inadequate sizing. By adhering to these best practices, engineers can create circuit boards that not only perform well but also withstand the rigors of everyday use in electronic applications.

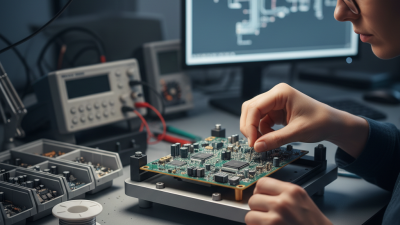

When designing an effective electronic circuit board, the importance of thorough testing and prototyping cannot be overstated. Testing techniques, such as Automated Optical Inspection (AOI) and In-Circuit Testing (ICT), are essential for ensuring that each component functions correctly and that no manufacturing defects are present. According to industry reports, 30% of circuit board failures can be attributed to manufacturing errors, making these testing methods critical in catching issues early in the development process.

Prototyping is another key phase that can significantly enhance the effectiveness of a circuit board design. Utilizing rapid prototyping techniques allows designers to quickly iterate on design changes and validate functionality. In a study by the IPC (Association Connecting Electronics Industries), it was found that teams employing rapid prototypes saw a 40% reduction in time-to-market for new products. This can be achieved through methods such as 3D printing of PCB layouts and using simulation software to anticipate potential electrical performance issues before physical prototypes are made.

Incorporating specific tips into the design process can lead to better outcomes. Firstly, always ensure you have a robust testing plan in place prior to production, which includes both pre- and post-manufacturing inspections. Secondly, leverage modern software tools for circuit simulation to visualize potential outcomes and prevent costly modifications later on. Lastly, engage in iterative prototyping to refine your designs based on user feedback and performance metrics continuously. These strategies not only enhance the functionality of the circuit board but also optimize the design process itself.

| Tip Number | Tip Description | Importance Level | Testing Technique | Prototyping Method |

|---|---|---|---|---|

| 1 | Start with a clear schematic diagram. | High | Simulation Testing | Breadboarding |

| 2 | Choose the right components for durability. | Medium | Fail Test | 3D Printing |

| 3 | Keep traces short to avoid interference. | High | Signal Integrity Testing | Prototype Boards |

| 4 | Incorporate proper grounding techniques. | High | Ground Bounce Testing | Prototype Iteration |

| 5 | Design for manufacturability (DFM). | Medium | Design Review | Test Fit |

| 6 | Conduct thermal analysis during design. | High | Thermal Imaging | Mock-ups |

| 7 | Utilize adequate decoupling capacitors. | High | Power Integrity Testing | Functional Prototyping |

| 8 | Test for EMI when necessary. | Medium | EMI Testing | Iterative Testing |

| 9 | Plan for future upgrades in your design. | Medium | Regression Testing | Flexible Prototyping |

| 10 | Document all changes to the design. | Low | Documentation Review | Change Logs |