In the rapidly evolving landscape of electronics manufacturing, circuit board fabrication stands as a cornerstone for innovation and functionality. As modern devices become increasingly sophisticated, the demand for high-quality printed circuit boards (PCBs) grows correspondingly. Expert in the field, Dr. Elizabeth Chen, a seasoned engineer with over 15 years of experience in PCB design and fabrication, emphasizes the importance of this process by stating, "Without precise circuit board fabrication, even the most advanced electronics would fail to operate effectively." This underscores the critical role that meticulous craftsmanship plays in the performance of electronic devices.

Circuit board fabrication not only involves the creation of the physical substrate upon which electronic components are mounted but also ensures that these components connect correctly to form a functional whole. As the industry shifts toward miniaturization and greater complexity, the techniques and technologies employed in circuit board fabrication continually evolve, facilitating advancements in everything from consumer electronics to aerospace applications. Understanding the nuances of this process is essential for anyone looking to grasp how modern electronics manufacturing thrives. As we delve deeper into the intricacies of circuit board fabrication, it becomes clear that this foundational element is pivotal in bringing cutting-edge technology to life, ultimately shaping the future of electronics.

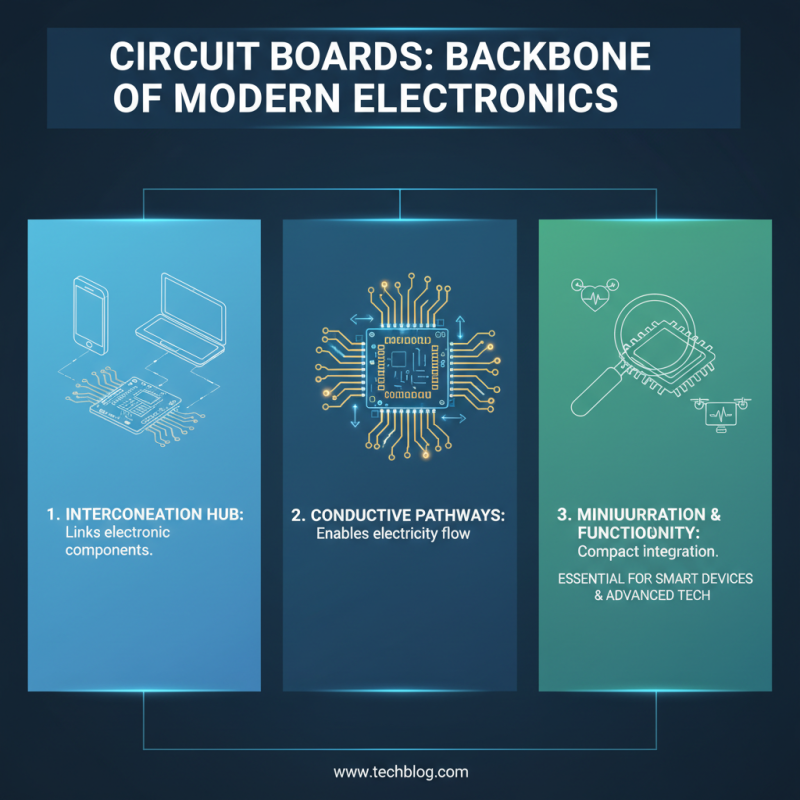

Circuit boards serve as the backbone of modern electronics, acting as a crucial interface that facilitates the connection and communication between various electronic components. These boards are designed with a complex network of conductive pathways that allow electricity to flow seamlessly through devices, enabling them to perform their intended functions. In devices ranging from smartphones to advanced medical equipment, circuit boards provide a compact and efficient means of integrating multiple functionalities within a limited space, showcasing their critical role in miniaturization trends in technology.

Moreover, the versatility of circuit boards ensures that they meet the diverse requirements of various applications. They can be customized in terms of size, layout, and material, allowing manufacturers to innovate and adapt their designs according to specific industry needs. As technology continues to evolve, particularly in areas such as IoT (Internet of Things) and wearable tech, the demand for advanced circuit board designs is becoming increasingly evident. This adaptability not only enhances product performance but also supports the rapid pace of electronics development, affirming the importance of circuit boards in the contemporary manufacturing landscape.

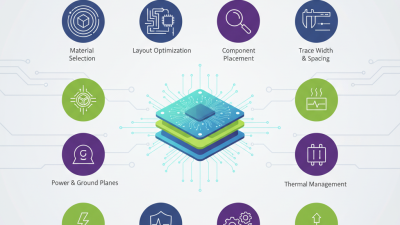

The circuit board fabrication process is a critical component in the manufacturing of modern electronics. This process typically begins with the design of the printed circuit board (PCB), where engineers utilize advanced software to create layouts that define the electrical pathways and components. According to the IPC, the global PCB market is projected to reach $82 billion by 2025, underscoring the significance of efficient fabrication processes. The first step involves material selection, where substrates like FR-4, a glass-reinforced epoxy laminate, are commonly used due to their favorable electrical properties and thermal stability.

After material selection, the fabrication process proceeds with photolithography, where light-sensitive chemicals coat the surface of the PCB. This step is crucial for transferring the circuit design onto the board. Following this, etching removes excess copper, creating the desired circuit pattern. According to a report from Research and Markets, advancements in technologies, such as additive manufacturing and automated inspection systems, are expected to further enhance the efficiency and accuracy of PCB production. The layered assembly involving drilling, plating, and solder mask application also plays a vital role in ensuring that the final product meets the industry standards for performance and reliability, shaping the backbone of the electronic devices we use today.

The fabrication of circuit boards is pivotal in modern electronics, as these boards serve as the backbone of most electronic devices. The materials used in circuit board manufacturing significantly influence the performance and reliability of the final products. Commonly employed materials include copper, epoxy resin, and various laminates, each serving a distinct purpose in the construction of these boards.

Copper is the primary material used for electrical connections within circuit boards. Its excellent conductivity allows for efficient signal transmission, essential for high-speed electronics. Epoxy resin, on the other hand, acts as an insulating layer that binds the circuit board together while protecting the conductive pathways. Additionally, different types of laminates, such as FR-4, are utilized to provide structural integrity and thermal stability, ensuring that the boards can withstand the demands of modern electronic applications. Each material not only enhances the functionality of the circuit boards but also contributes to the overall durability and longevity of electronic devices.

The production of circuit boards is pivotal in the realm of modern electronics manufacturing, yet it poses several challenges that can significantly impact the final product's quality and reliability. According to a report by IPC, the world’s leading association for electronics manufacturing, the industry has faced a 6% increase in defects over the past year, primarily due to complexities in circuit board design and the increasing miniaturization of components. As circuits become denser, manufacturers must ensure precise alignment and robust connections, which demand advanced fabrication techniques and stringent quality control measures.

Quality control remains a critical hurdle in circuit board production, as the repercussions of defects can be severe. A study by the Electronics Industry Association highlights that defects in circuit boards can lead to failure rates of up to 30% in end products, contributing to significant costs in terms of warranty claims, recalls, and brand reputation. Implementing comprehensive testing protocols, such as Automated Optical Inspection (AOI) and X-ray inspection, has become essential in mitigating these risks. As production technologies evolve, manufacturers are also investing in real-time data analytics to enhance their quality assurance processes, thus ensuring that circuit boards meet the rigorous standards required in an increasingly demanding market.

The advancement of circuit board technology is pivotal in shaping the future of electronics manufacturing. With the global printed circuit board (PCB) market expected to reach approximately $85 billion by 2027, driven by increasing demand in sectors like telecommunications, automotive, and consumer electronics, manufacturers are compelled to innovate. New technologies, such as flexible circuits, are gaining traction due to their lightweight and compact nature, allowing for innovative products that can fit into smaller spaces while maintaining functionality.

Moreover, the integration of automation and artificial intelligence in PCB manufacturing processes is revolutionizing production efficiency. According to a recent industry report, adopting automated assembly techniques can reduce production costs by up to 30% and enhance precision in component placement.

Additionally, advancements in materials science, including the development of high-frequency and high-density interconnect PCBs, are crucial as they enable devices to operate at faster speeds with improved reliability. These trends reflect a broader move towards the miniaturization of electronic devices, making reliable circuit board fabrication more essential than ever in the electronics manufacturing landscape.