Choosing the right PCB board assembly service is crucial for the success of any electronic project. A well-assembled PCB can significantly impact the performance, reliability, and overall outcome of your product. As the demand for high-quality electronics continues to rise across various industries, selecting a service that meets your specific needs becomes more important than ever. Understanding the factors that influence PCB board assembly can help streamline your project and save both time and resources.

In this fast-evolving market, the choices available may seem overwhelming, but there are essential criteria to consider when making your selection. Factors such as the provider's expertise, technologies used, quality assurance processes, and customer support play a significant role in ensuring the assembly meets the industry's standards. Furthermore, understanding your project's unique requirements—such as volume, budget, and timeline—will help you align with a service that can deliver precisely what you need.

Ultimately, investing the time to thoroughly evaluate your options will result in a partnership that enhances your project's success. By following the best practices in selecting the right PCB board assembly service, you can ensure that your electronic devices achieve their desired functionality and reliability in the competitive marketplace.

When embarking on a PCB assembly project, understanding the specific requirements of your project is paramount. Various factors can influence your decision, including the complexity of the design, the volume of production, and the desired turnaround time. According to a report by IPC, the global trade association for the electronics manufacturing industry, more than 60% of assembly issues arise from miscommunication regarding project requirements, highlighting the importance of clear specifications before engaging with a PCB assembly service.

When defining your project requirements, consider the following aspects:

the type of components to be used (surface mount or through-hole), the size of the board, and the functional testing needed post-assembly. Gathering detailed information about the intended application can also guide your choice of assembly service. A comprehensive understanding can aid in selecting a service that is well-equipped to handle your specific needs, potentially preventing costly revisions later.

Tips: Communicate openly with potential assembly partners about your project's nuances. This proactive approach can uncover hidden challenges and ensure you're choosing a service with the necessary capabilities and expertise. Additionally, assess their quality control processes, as robust QC measures can significantly impact the reliability of your final product. Lastly, evaluate their experience with prototypes versus high-volume production, as this can affect lead times and cost efficiency.

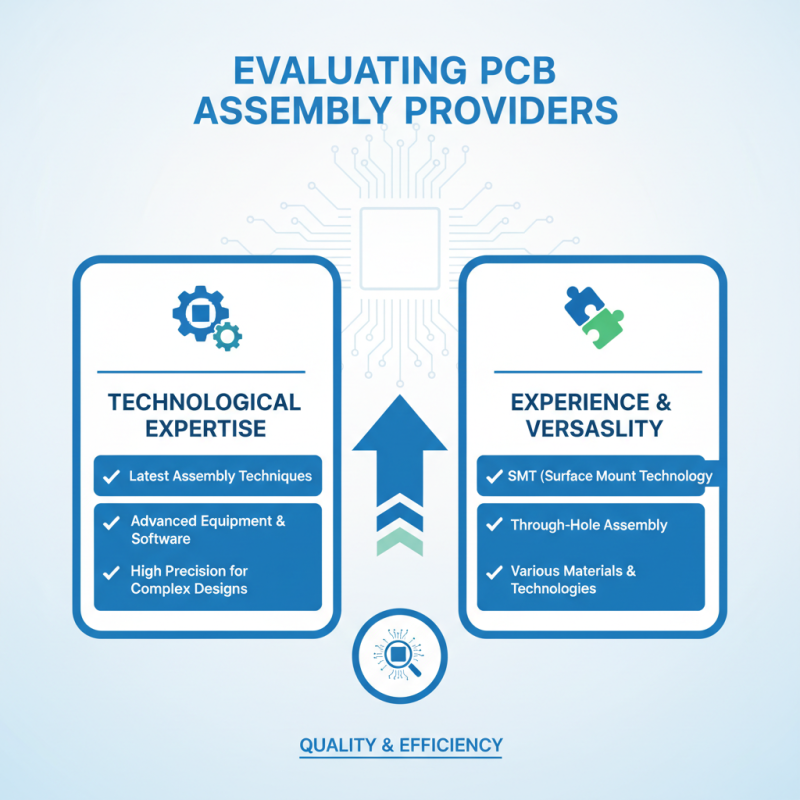

When evaluating the capabilities of PCB assembly service providers, consider several crucial factors that can significantly influence the quality and efficiency of your project. Firstly, assess their technological expertise. A reputable provider should have access to the latest assembly techniques, equipment, and software tools, ensuring they can handle complex designs and maintain high precision. Additionally, evaluate their experience with various materials and technologies, such as surface mount technology (SMT) and through-hole assembly, to determine if they can meet your specific project needs.

Tips: When reviewing potential providers, request samples of their previous work and inquire about their certifications. This will give you insights into their quality control processes and adherence to industry standards. Furthermore, consider their ability to scale operations. Whether you need a small prototype or a large production run, ensure that the provider can adjust to your project’s demands without compromising quality.

Another critical aspect is communication and support. A good PCB assembly service should offer clear communication channels and be responsive to your inquiries. This is vital for troubleshooting any issues that may arise during the assembly process. Additionally, having dedicated customer support can provide peace of mind, knowing that assistance is readily available if needed.

Tips: Establish a point of contact who understands your project requirements. Regular updates and open dialogue can prevent misunderstandings and foster a collaborative working relationship, ultimately leading to a successful assembly outcome.

When selecting a PCB board assembly service, understanding costs and lead times is essential for project success. According to industry reports, the average cost for PCB assembly services can range from $0.10 to $0.50 per component, depending on complexity and volume. For instance, high-mix low-volume PCB assemblies often incur higher costs due to the setup time involved, which can significantly impact overall budgeting. Similarly, factors such as the type of package, board size, and the number of layers also play a crucial role in determining the final expenses.

Lead times are another critical consideration in the selection process, as they can vary dramatically between providers. Industry standards suggest typical lead times for PCB assembly can range from one week for expedited services to several weeks for standard offerings. A survey conducted in 2022 revealed that 60% of companies experienced delays in product development due to longer than expected lead times. Thus, it is vital to evaluate not only the costs but also the reliability of a service provider in meeting deadlines. A well-informed choice can ensure that your project remains on schedule and within budget, aligning both financial and temporal expectations effectively.

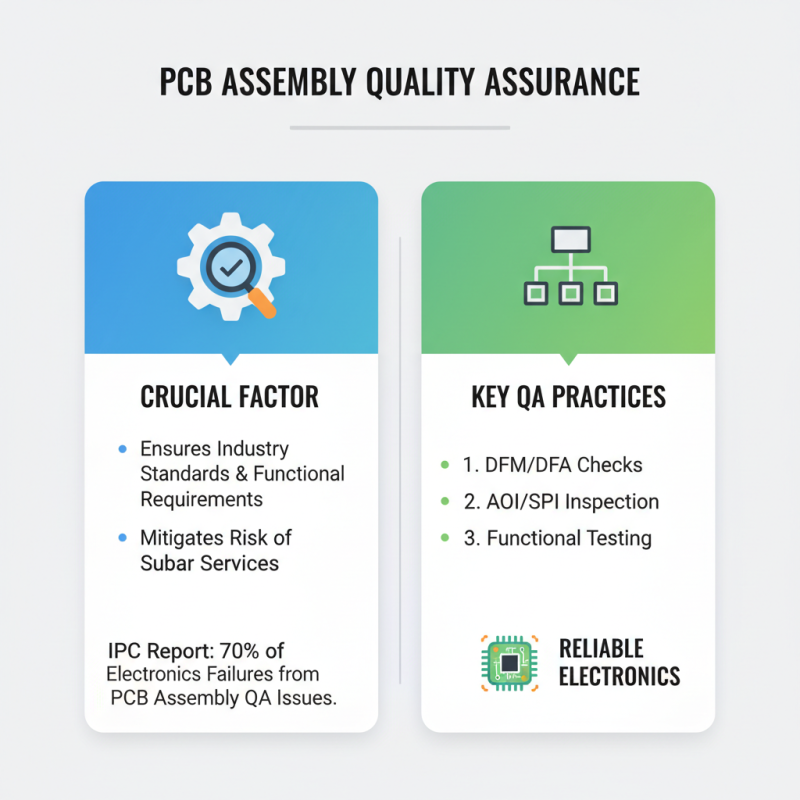

When selecting a PCB board assembly service, one of the most crucial factors to consider is the quality assurance practices in place. Quality assurance (QA) is essential in ensuring that the finished PCB boards meet industry standards and functional requirements. A report from IPC, a global association for the electronics industry, indicates that approximately 70% of field failures in electronics can be traced back to quality issues during the PCB assembly process. By understanding and evaluating QA practices, you can mitigate the risks associated with subpar assembly services.

A robust quality assurance framework typically includes several critical components such as incoming material inspections, in-process quality checks, and final product testing. For instance, services that employ statistical process control (SPC) can significantly reduce defects. According to a study published by the Electronics Manufacturers Association, companies that implement SPC and other quality initiatives report an average defect rate reduction of over 40%. Furthermore, certifications such as ISO 9001 or IPC-A-610 can serve as indicators of a manufacturer’s commitment to quality. These certifications ensure that the service provider adheres to internationally recognized standards, ultimately leading to enhanced operational efficiency and reliability of the assembled PCBs.

Moreover, the integration of Automated Optical Inspection (AOI) technology in the assembly process has been shown to improve defect detection rates significantly. A survey by the International Electronics Manufacturing Initiative revealed that implementing AOI can lead to a 90% increase in the detection of soldering defects early in the assembly phase. Therefore, when choosing a PCB assembly service, assessing their quality assurance practices not only impacts the immediate project requirements but also contributes to the long-term success and sustainability of your products.

When selecting a PCB board assembly service, customer support and communication should be at the forefront of your decision-making process. Effective communication is not just about answering queries; it encompasses proactive engagement, responsiveness, and transparency throughout the project lifecycle. A provider should have clear channels for communication, ensuring that you can easily reach out for updates or address issues. Look for companies that offer multiple modes of contact, such as email, phone, and live chat, allowing for flexibility in how you connect.

Moreover, assessing a potential assembly service's customer support can make all the difference in the success of your project. Promptness in responding to inquiries often reflects a company’s commitment to customer satisfaction. In addition, inquire about their processes for handling revisions or troubleshooting issues that may arise during assembly. A reliable provider will not only have robust systems in place but will also involve you in the decision-making process, keeping you informed and engaged from initial discussions through to the final delivery. This collaborative approach can help ensure that the final product meets your specifications and quality standards.