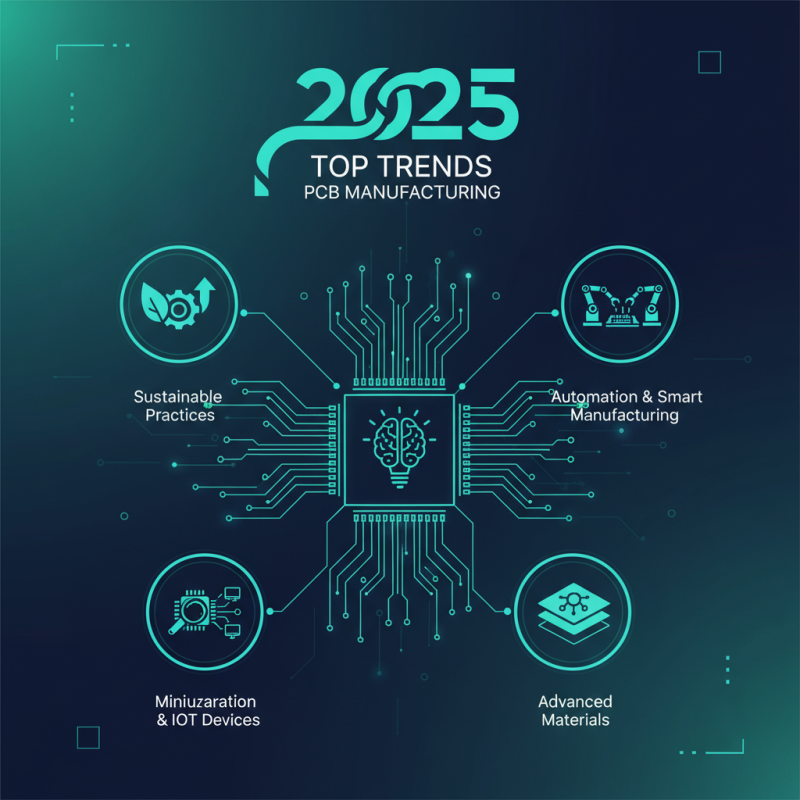

In the rapidly evolving landscape of technology, keeping up with the latest trends in PCB board manufacturing is crucial for businesses striving to maintain a competitive edge. As we approach 2025, various innovations and methodologies are set to redefine how printed circuit boards are designed, manufactured, and utilized. Leading industry expert Dr. Emily Richards, a renowned figure in the realm of PCB technology, asserts, "The future of PCB board manufacturing lies not just in speed and efficiency, but in sustainable practices that will drive our industry forward."

The importance of staying ahead in the PCB board manufacturing sector cannot be overstated. The integration of advanced materials, automation, and smart manufacturing processes will significantly influence production efficiency and product reliability. As organizations navigate these advancements, it's essential to adopt practices that align with both market demands and technological capabilities.

Moreover, the increasing emphasis on miniaturization and IoT devices presents unique challenges and opportunities within the PCB board manufacturing domain. Companies that can adapt to these shifting trends will not only enhance their operational efficiency but also contribute to a more sustainable future. In this detailed exploration of the top trends expected in 2025, we aim to provide insights that will empower industry players to strategically position themselves for success.

Emerging technologies are redefining PCB board manufacturing, and by 2025, several innovations are expected to significantly influence the industry. One of the most prominent trends is the integration of Artificial Intelligence (AI) and Machine Learning (ML) into production processes. These technologies can enhance quality control and optimize manufacturing workflows by analyzing production data in real-time. This leads to reduced errors, improved efficiency, and the ability to predict maintenance needs, ultimately driving down costs and increasing output.

Another pivotal trend is the rise of flexible and printed electronics, which are paving the way for more versatile PCB designs. As devices become smaller and more complex, the demand for lightweight and adaptable circuit boards is surging. Advanced materials, such as organic substrates and flexible polymers, enable the creation of PCBs that can be easily integrated into various applications, from wearables to IoT devices. Additionally, innovations in additive manufacturing techniques are enhancing the production capabilities, allowing for intricate designs and faster prototyping.

Moreover, sustainability is emerging as a key focus, with more manufacturers adopting eco-friendly practices and materials. This shift towards green manufacturing not only meets regulatory requirements but also appeals to environmentally conscious consumers. Techniques such as using lead-free solders, recycling materials, and minimizing waste are becoming standard practices, ensuring that the PCB manufacturing process is not only efficient but also responsible. As these technologies continue to evolve, they will play a crucial role in shaping the future landscape of PCB manufacturing.

In recent years, the printed circuit board (PCB) manufacturing industry has seen a transformative shift towards sustainability, driven by consumer demand and regulatory pressures. A report by the IPC (Institute for Printed Circuits) indicates that over 60% of PCB manufacturers are currently implementing eco-friendly practices in their production processes. This includes the adoption of lead-free soldering, reduction of hazardous materials, and increased recycling efforts. As companies strive to align with ISO 14001 standards, they are not only enhancing their environmental performance but also reducing long-term operational costs.

Another key trend is the integration of life cycle assessment (LCA) tools in PCB production. A study by the International Journal of Life Cycle Assessment reveals that companies using LCA can reduce their environmental impact by up to 30%. This approach allows manufacturers to evaluate each stage of the PCB life cycle—from raw material extraction to end-of-life disposal—thereby identifying opportunities for waste reduction and resource optimization. Moreover, there is an increasing emphasis on using biodegradable materials, which not only comply with environmental regulations but also appeal to eco-conscious consumers, contributing to a more sustainable industry future.

The advancements in materials science are critical drivers in enhancing the performance of PCB (Printed Circuit Board) manufacturing. One of the most significant trends is the emergence of high-frequency laminates that effectively reduce signal loss and improve the overall efficiency of electronic devices. These materials are engineered to maintain integrity at elevated temperatures and frequencies, making them ideal for applications in telecommunications, aerospace, and automotive industries. By utilizing these advanced materials, manufacturers can produce PCBs that not only meet but exceed the rigorous performance standards set by modern electronics.

Additionally, innovations in flexible materials are paving the way for the development of conformable PCBs that can fit complex shapes and form factors. This flexibility increases design options for engineers and allows for more compact and lightweight devices without sacrificing performance. Moreover, environmentally friendly materials are becoming increasingly popular, as manufacturers seek sustainable solutions without compromising on quality or durability. The integration of these advanced materials not only enhances the reliability and longevity of PCBs but also significantly contributes to reducing the carbon footprint of the manufacturing process.

| Trend | Description | Materials Used | Expected Benefits |

|---|---|---|---|

| High-Frequency PCB | Utilization of materials that support higher frequency applications. | PTFE (Polytetrafluoroethylene), Rogers Materials | Reduced signal loss, improved performance in RF applications. |

| Flexible PCBs | Increasing demand for flexible design solutions in electronic devices. | Polyimide Films, PET | Lightweight, thinner profiles, and space-saving designs. |

| Environmentally Friendly Materials | Shift towards sustainable materials to reduce environmental impact. | Biodegradable PCBs, Lead-free Materials | Reduced toxicity, compliance with environmental regulations. |

| 3D Printed PCBs | Innovative manufacturing method allowing complex geometries. | Conductive Inks, Photopolymers | Rapid prototyping, customization, reduced material waste. |

| Advanced Thermal Management Materials | Use of materials designed for superior thermal conductivity. | Thermal Interface Materials, Graphene | Enhanced heat dissipation, improved reliability of electronic devices. |

The integration of automation and artificial intelligence (AI) in printed circuit board (PCB) manufacturing processes is revolutionizing the industry, ushering in a new era of efficiency and precision. According to a report by the IPC, a global trade association, the adoption of automation technologies in PCB production has increased by over 40% from 2020 to 2023. This surge is primarily driven by the need for reducing production costs and minimizing human error. Automated systems can execute repetitive tasks with high accuracy, such as component placement and soldering, ultimately improving production speed and yield rates.

AI technologies, particularly machine learning algorithms, are becoming instrumental in enhancing quality control and predictive maintenance in PCB manufacturing. Research from MarketsandMarkets indicates that the AI in manufacturing market is expected to grow from $1.4 billion in 2022 to $16.7 billion by 2026, reflecting the rising importance of AI applications in industrial settings. By analyzing data from past production runs, AI can identify potential defects and provide real-time insights, allowing manufacturers to adjust processes proactively. This capability not only leads to higher reliability in end products but also significantly reduces downtime, as equipment can be maintained before failures occur. The synergy between automation and AI is paving the way for smarter, more efficient PCB manufacturing processes, positioning companies to meet the demands of a fast-evolving market.

The evolving landscape of the PCB (printed circuit board) industry presents several challenges that manufacturers must navigate to remain competitive. One major issue is the rapid advancement of technology, which demands more complex and miniaturized PCB designs. As devices become smaller and more powerful, manufacturers must invest in innovative techniques and materials to accommodate these changes. This necessitates a shift to advanced manufacturing processes, which can be costly and require specialized knowledge, putting pressure on companies to upskill their workforce or invest in automation.

Additionally, environmental regulations are evolving, requiring PCB manufacturers to adopt more sustainable practices. This transition involves not only compliance with stricter standards but also the need for developing eco-friendly materials and efficient waste management systems.

To tackle these challenges, companies are exploring partnerships with technology firms and investing in research and development. Implementing sustainable practices not only helps in compliance but can also bolster a manufacturer's reputation and marketability in an increasingly environmentally-conscious market.

Staying ahead in the PCB industry thus requires balancing technological advancement with sustainability efforts, allowing companies to thrive amidst the challenges of this fast-paced sector.