In the rapidly evolving world of technology, circuit board assembly stands at the forefront of innovation, serving as the backbone for a multitude of devices ranging from smartphones to sophisticated industrial machinery. As the industry grows, understanding the key players in circuit board assembly becomes essential for businesses aiming to stay competitive. According to Dr. Emily Carter, a leading expert in electronic manufacturing, "The quality of circuit board assembly can significantly influence the performance and longevity of electronic products." This insight underscores the importance of selecting the right partners in this critical phase of product development.

The year 2025 promises to showcase some of the most advanced and reliable circuit board assembly companies committed to precision and efficiency. With a focus on delivering superior quality and adhering to rigorous industry standards, these companies are poised to shape the future of technology. By exploring the top 10 circuit board assembly firms, organizations can gain valuable insights into which providers can best meet their needs, ensuring that their products are built on a foundation of excellence.

As we delve into this curated list, we will highlight companies that stand out not only for their technical capabilities but also for their customer-centric approach, innovation, and commitment to sustainable practices in the circuit board assembly industry. Understanding who these players are will empower businesses to make informed decisions that enhance their competitive edge.

In 2025, the circuit board assembly (CBA) industry is witnessing transformative changes driven by innovative companies at the forefront of technological advancement. Leading firms are incorporating automation, artificial intelligence (AI), and advanced materials to enhance production efficiency and reduce costs. According to a recent industry report by IPC, the global printed circuit board market is projected to reach $80 billion by 2025, reflecting a compound annual growth rate (CAGR) of approximately 4.5%. This growth is largely fueled by the rising demand for high-performance electronics in sectors such as automotive, healthcare, and telecommunications.

As the industry evolves, companies are increasingly focusing on sustainability practices. Utilizing eco-friendly materials and energy-efficient manufacturing processes has become imperative. For instance, recent studies suggest that businesses adopting sustainable practices can improve their brand reputation and reduce production costs by up to 30%.

**Tips:** Consider partnering with CBA firms that emphasize transparency in their supply chain and prioritize eco-conscious manufacturing. Additionally, stay informed about the latest technologies being integrated into assembly processes to ensure you're leveraging the best quality and service available in the market. Embracing these innovations not only enhances product reliability but also positions your business as a leader in a competitive landscape.

The realm of circuit board assembly (CBA) is undergoing a technological revolution, with innovative solutions reshaping how products are manufactured. According to a report by the IPC (Institute of Printed Circuits), the global CBA market is expected to grow from $67 billion in 2022 to over $80 billion by 2025, driven by advancements in automation and smart technology. These innovations not only enhance production efficiency but also reduce errors, which is critical in an industry where precision is paramount.

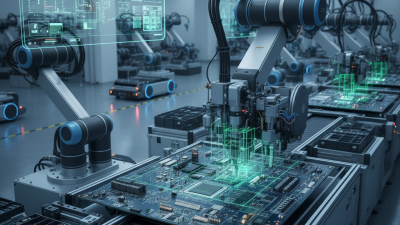

One of the pivotal technologies propelling this growth is the implementation of Industry 4.0 principles in circuit board assembly. By integrating IoT (Internet of Things) devices and AI (Artificial Intelligence), companies are able to monitor production processes in real-time, optimizing workflows and predicting maintenance needs. A study by McKinsey highlights that companies utilizing these technologies can see productivity increases of up to 20-30%. Additionally, the adoption of robotics for soldering and assembly tasks has significantly decreased cycle times, further streamlining operations and allowing for faster time-to-market. As we look toward 2025, these innovative technologies will undoubtedly play a critical role in defining the future landscape of circuit board assembly.

When selecting a circuit board assembly (CBA) partner, several key factors should guide your decision-making process. First and foremost, assess the company's expertise and experience within the specific industry relevant to your products. A partner with extensive knowledge in your field can better navigate the unique challenges and requirements that may arise, ensuring a smoother assembly process and higher quality outcomes.

Another critical aspect to consider is the technology and equipment employed by the CBA provider. Advanced machinery and modernization in their processes can significantly impact production efficiency and the precision of the final product. Additionally, inquire about their quality control measures, including certifications and testing protocols, to ensure that their standards align with your expectations. A robust quality assurance process can mitigate risks associated with defects and inefficiencies, ultimately enhancing your product's reliability in the marketplace.

In the ever-evolving landscape of electronics manufacturing, circuit board assembly (CBA) companies play a pivotal role in determining the quality and reliability of electronic devices. A comparative analysis of the top circuit board assembly service providers reveals a diverse array of strengths and specialties, from rapid prototyping to large-scale production. Companies like Jabil and Flextronics stand out due to their advanced manufacturing technologies and extensive global supply chains, enabling them to cater to a broad range of industries including automotive, healthcare, and consumer electronics.

Additionally, emerging players such as Sanmina and PCBWay have gained recognition for their commitment to customer service and flexibility in production volumes. These companies often leverage innovative techniques, such as automated assembly and testing processes, to enhance efficiency and reduce lead times. By evaluating factors such as quality control measures, pricing, and technological capabilities, businesses can make informed decisions when selecting a CBA partner that aligns with their specific needs and industry demands.

The chart above illustrates the quality scores of the top 10 circuit board assembly providers for 2025. These scores are indicative of their service quality in the industry, providing an insight into their performance comparisons.

The landscape of circuit board assembly (CBA) is undergoing significant transformations, driven by technological advancements and shifting market demands. In 2025, we expect to see increased integration of automation and artificial intelligence in CBA processes, enhancing efficiency and reducing human error. Automated systems will likely streamline production lines, allowing companies to achieve higher precision and faster turnaround times, which are crucial in meeting the growing consumer expectations for electronic devices.

Moreover, with the rise of the Internet of Things (IoT) and smart devices, the demand for more complex and miniaturized circuit boards will continue to escalate. This trend necessitates a closer collaboration between CBA companies and their clients, ensuring that design and manufacturing processes align perfectly with innovative product requirements. Sustainability will also play a pivotal role, as companies are increasingly focusing on eco-friendly practices and materials in their production processes. By embracing these future trends, the top circuit board assembly companies will not only enhance their operational effectiveness but also contribute positively to the environment and the overall tech ecosystem.